29 Nov Automating 10 crucial manufacturing documents with intelligent document processing (IDP)

As the manufacturing sector accelerates its journey into the digital era, the administrative side of operations demands streamlined data management and document processing

Understanding the IDP advantage

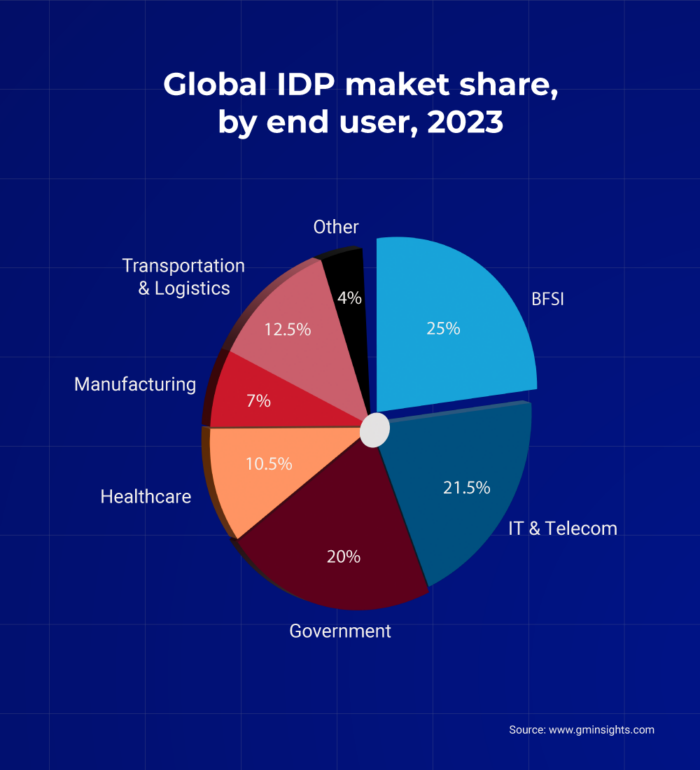

In the realm of industry 4.0 leading to the industry 5.0, data management becomes pivotal. The surge in automation and robotics generates a colossal amount of business data, demanding advanced systems to efficiently implement processes. IDPs like Docketry stands as a robust solution, ensuring accurate reporting and effective data management. The manufacturing sector has been witnessing a continuous flow of data, ranging from proposals, contracts, invoices, to quality control reports. Much of this data exists in unstructured or semi-structured document formats, requiring manual effort and time for accurate entry into central repositories or document management systems.

The need for accelerated data availability

In a world where data drives business decisions, the key to staying ahead lies in expediting data availability and management. This is particularly crucial in manufacturing, where timely access to data impacts customer service, operations, and entire processes. Delays in data availability not only affect sales and revenue but also impact return business. This is where Docketry steps in, empowering manufacturing companies to harness actionable data from unstructured or semi-structured documents right at the source. Let’s unravel the significance of IDP in manufacturing and benefits it brings, focusing on the automation of ten critical

documents.

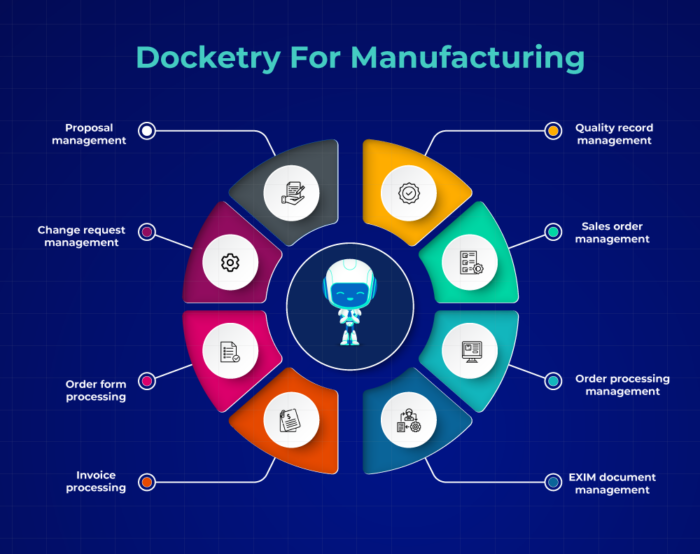

Automating key manufacturing documents with IDP

Let’s explore ten essential documents in manufacturing that can be seamlessly automated

with IDP:

1. Purchase orders

IDP can extract vital information from purchase orders, including vendor name, order number, item description, quantity, price, and delivery date. It validates this data against inventory and pricing databases, updating order statuses in the ERP system. Additionally, IDP can generate confirmation emails or invoices for vendors and alert procurement teams of discrepancies or delays.

2. Invoices

IDP scans and captures data from invoices, such as supplier name, invoice number, date,amount, tax, and payment terms. It matches invoice data with corresponding purchase orders and receipt information, flagging errors or exceptions. Integration with accounts payable systems allows IDP to initiate the payment process or send reminders to suppliers.

3. Quality control reports

Digitizing and analyzing data from quality control reports becomes efficient with IDP. It processes information like product name, batch number, inspection date, test results, and defects. IDP compares this data with quality standards, identifies non conformities or deviations, and generates quality certificates or rejection notices.Insights for quality improvement and compliance are also provided.

4. Shipping and receiving records

IDP reads and processes data from shipping and receiving records, covering shipment number, carrier name, tracking number, origin, destination, weight, and delivery date. It verifies data with order and invoice details, updating inventory and logistics systems. Additionally, IDP can create shipping labels or packing lists and notify customers or suppliers of delivery statuses.

5. Work orders

IDP extracts and organizes data from work orders, such as customer name, order number, product name, quantity, specifications, and due date. Assigning work orders to the appropriate production units or machines becomes seamless with IDP, allowing monitoring of progress and completion. IDP can also generate production reports or feedback forms for customers, optimizing production planning and scheduling.

6. Equipment maintenance logs

Converting and interpreting data from equipment maintenance logs is simplified with IDP. It handles information like equipment name, serial number, maintenance date, service type, and technician name. IDP updates equipment history and warranty records, calculates maintenance costs and performance indicators, and schedules the next maintenance service or alerts the maintenance team of any issues.

7. Employee time sheets

IDP captures and validates data from employee time sheets, including employee name, ID number, department, shift, hours worked, overtime, and leave. Integration with payroll and human resources systems allows IDP to compute wages and benefits, generate pay slips or tax forms, and track attendance and productivity.

8. Training manuals

Scanning and structuring data from training manuals becomes interactive with IDP. It processes topics, objectives, instructions, examples, and quizzes, creating engaging trainingmodules or courses. These can be delivered through learning management systems, with IDP assessing learning outcomes and feedback, providing recommendations for improvement and certification.

9. Safety compliance documents

IDP recognizes and classifies data from safety compliance documents, including safety policies, procedures, regulations, audits, and incidents. Centralized storage and management of this data ensure accessibility and availability for relevant stakeholders. IDP also generates safety reports or alerts for management, facilitating compliance and risk management processes.

10. Product specifications

IDP analyzes and extracts data from product specifications, covering product name, category,features, dimensions, materials, and functions. This data is utilized to create product catalogs or brochures for customers, showcasing product information and benefits. IDP supports innovation and marketing activities by using the data to design and develop new products or enhance existing ones.

Conclusion

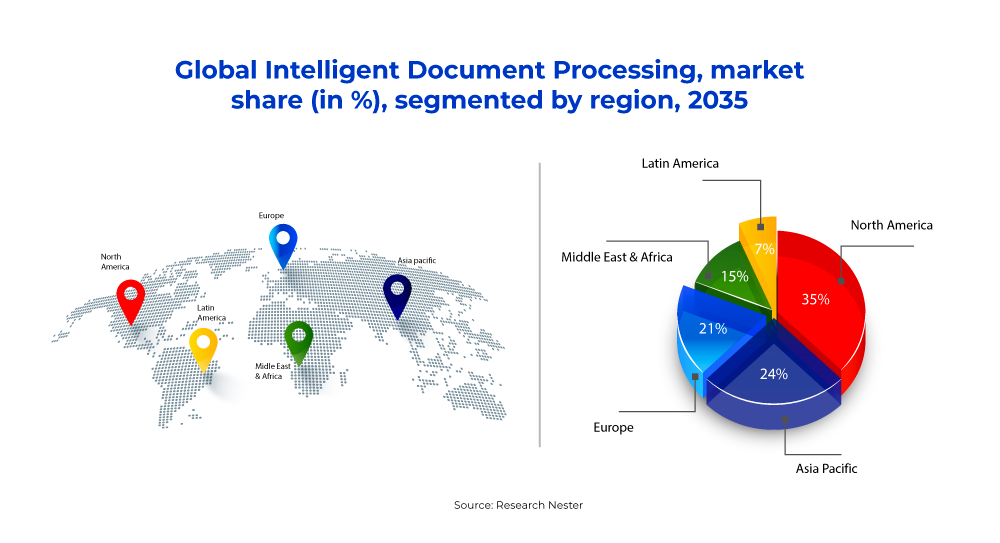

Embracing IDP in manufacturing is not just a technological upgrade; it’s a strategic move towards efficiency, accuracy, and competitiveness. Docketry helps you automate crucial documents that not only saves time and resources but also positions manufacturing companies at the forefront of revolutionary growth. As the manufacturing sector continues its digital journey, IDP stands as a beacon, illuminating the path towards a future where data is not just managed but harnessed for unparalleled growth and success.